How well do you know your sewing machine? Let’s help you understand one component a little better. The tension thread adjuster is located on your sewing machine and it makes the thread either tighter or looser depending on which setting you need. When sewing a lockstitch, the sewing machine tension numbers are very important.

If the tension isn’t perfect, the knots between the stitches will be visible along the seam. This will make the garment look untidy and unfinished. Don’t be afraid of the sewing machine tension settings. Instead, learn to use them correctly and take your sewing to a whole new level with the help of our article.

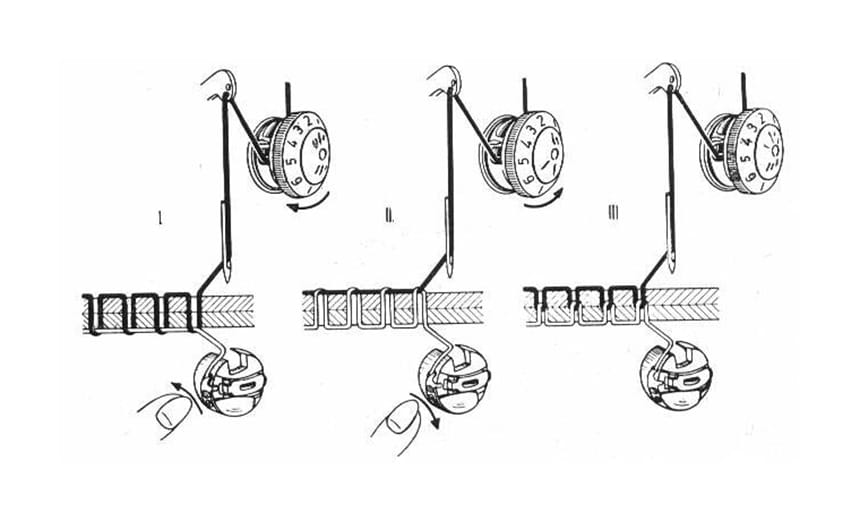

When threading your sewing machine, the tension should be perfectly balanced on both sides. You shouldn’t be able to see loops on either side of the material.

When threading your sewing machine, the tension should be perfectly balanced on both sides. You shouldn’t be able to see loops on either side of the material.

Before adjusting the tension on the sewing machine, there are several tests you can perform. Make sure there are no other issues and perform a thread test before setting the tension manually.

The easiest way to test your thread tension is by threading the machine with another color thread. The top thread will be one color and the bottom thread will be a different one. When you sew, you will be able to see where the problem is.

If you need a bit of help with threading, invest in machines like the SINGER Mechanical MX60 that has pre-set stitch length and width control for simple stitch selection.

Sometimes, the bobbin is wound too tightly and this affects the tension on the machine. The thread can sometimes become snagged if it’s wound incorrectly.

Of course, the quality of your machine also determines how it performs in terms of tension settings. That’s why it’s wise to invest in one of the quality sewing machine models on today’s market.

Fluff and excess pieces of fabric can become caught in the wheels of the machine. Use a small paintbrush to clean the wheels and remove any debris that may be trapped. This should be done every time you want to use the machine.

Check the eye of the needle for fluff and make sure the machine is clean before you switch it on.

Using the correct sewing machine for the type of job you’re busy with will also make sewing a breeze. However, it’s still important that everything in the machine is balanced. The thread should be the same thickness and weight on both sides. If one is heavier than the other, it will be unbalanced and cause extra tension.

The needle on your sewing machine should be sharp and be able to go through the fabric easily. If the needle is blunt, the needle will struggle to penetrate the material and this can affect the tension on the sewing machine.

Check that the needle is the correct one for the type of machine you have, and that it’s installed correctly. Different types of material will require different needles. As an example of how your equipment affects the outcome, The Brother CS7000X has a metal frame & needle that doesn’t move. The durable metal frame design allows the sewing machine to tackle any project, and the needle is fitted in place while you work, allowing more precise stitching and even lines.

The top thread and the bobbin should be the same brand, weight and quality. If they don’t match then the tension on the machine will be incorrect. Use the highest quality products that you can afford.

Your manual should tell you how to correctly set your bobbin and how to fix sewing machine tension. The bobbin should be inserted correctly to ensure that the machine operates smoothly. The bobbin thread should be threaded through the bobbin spring located at the bottom of the case.

Your manual should tell you how to correctly set your bobbin and how to fix sewing machine tension. The bobbin should be inserted correctly to ensure that the machine operates smoothly. The bobbin thread should be threaded through the bobbin spring located at the bottom of the case.

Only adjust one thread at a time, or you could undo the work that you have already done and the tension still won’t be correct.

Threads come in a variety of thicknesses and quality types. Always use a high-quality thread in your machine. Cheaper alternatives may be tempting but they can damage the machine. Bad quality threads will break and could put your sewing project at risk.

Make sure that the top thread isn’t catching around the bottom of the spool. This can affect the tension. The thread shouldn’t be too tight or loose.

The type of fabric that you are sewing will affect the tension you need. Densely-woven fabric such as denim will require a higher level of friction.

Cotton or knitted fabrics are softer, so they need less friction, and less tension is needed when sewing with them. Sewing machine tension for cotton will be much less than a fabric such as leather.

If you are using a thicker fabric, remember you may need proper heavy-duty sewing machines.

Consult your owner’s sewing machine tension chart and choose the correct dial setting. Before you start sewing make sure the dials are in the correct position. Using the correct setting on the machine will make sewing much easier.

Consult your owner’s sewing machine tension chart and choose the correct dial setting. Before you start sewing make sure the dials are in the correct position. Using the correct setting on the machine will make sewing much easier.

The throat plate is a vital part of the sewing machine and damage often occurs from sewing over needles left in the fabric. If the plate is scratched or has pieces missing it could catch the thread from the bobbin. When a part is damaged in any way it should be replaced immediately.

Getting the tension just right is like performing a balancing act. The weight of the thread should be even and you must use the correct thread for the type of fabric.

Try not to use the dials to adjust the tension. First, make sure you have followed these tips and ruled out any other possible causes.

Once you have tried to troubleshoot the problem and your sewing machine tension is still wrong, it’s time to contact a professional.

Sewing machines need to be well-maintained and serviced regularly to keep it in tip-top shape. If you have more questions on this topic, leave a question for us.