If you are new to sewing and dressmaking, you can be forgiven for not having a clue about interfacing fabric Trusted Source Interfacing - Wikipedia Interfacing is a textile used on the unseen or “wrong” side of fabrics to make an area of a garment more rigid. en.m.wikipedia.org . With time, you’ll know more about it and why you need to use it. Although it is not the most complicated aspect of dressmaking, it can be confusing, especially for a beginner. However, it doesn’t need to be if you have the right guide to follow.

As a dressmaker, you want to make a dress that guarantees optimal use. Using interfacing fabric is a reliable way to add additional stability or stiffness to the fabric, thus preventing it from sagging.

We understand the challenge of finding the right guide for learning how to use interfacing fabric. Therefore, this article will explain the processes involved in using interfacing fabric and help you understand them.

Interfacing fabric is simply a fabric designed and used to make some parts of a garment stiffer and more stable. Essentially, dressmakers use it as an extra layer and apply it to the inside of garments such as pockets, cuffs, waistbands, and collars. The presence of this fabric adds shape, structure, support, and firmness to the garment.

Besides, dresses stabilized by interfacing fabric are often stronger and last longer than without it. Without interfacing fabrics, it’s difficult for garments such as coats and jackets to retain their shape with regular wear and tear.

Moreover, you need a heavy-duty sewing machine and a high-quality fabric cutting machine to get the job done. Also, you will need to apply interfacing to your fabric before approaching your sewing machine for hemming or stitching.

Contrary to what you might have thought, there are many types of interfacing fabric. There are two main types of interfacing, namely fusible and sew-in. There are also three main weaves, including woven, non-woven, and knit. Any of these interfacing fabrics can be used to stabilize a garment but you must use the right type for your piece. We will explain the different types of interfacing fabric below:

The fusible interfacing is arguably the easiest option available. It features a grid of glue coating on the wrong side. This interfacing requires the heat of a hot iron to fuse it into your garment. If done carefully and correctly, it will stay glued to the fabric.

If you’re a beginner in dressmaking, using fusible interfacing will be a lot easier for you. Although it works on most garments, it doesn’t work on some fabrics that don’t absorb heat well or are woven loosely. Also, this interfacing fabric does not work well on very textured fabrics.

Finding an excellent interfacing fabric is not difficult. According to several reviews, the Fusible Interfacing Lightweight Fabric from HENGYONGTA appears like the real deal. It adds lightweight structure and helps the garment to keep its shape. The product is a worthy choice if you’re dealing with lightweight fabrics.

If that doesn’t look like the right fit for your garment, the Lolona Fashion’s Fusible Interfacing may help. Many reviews say this product fuses strongly with the fabric and gives it strength, rigidity, and structure.

The sew-in interfacing is the complete opposite of fusible interfacing. While the latter has a glue backing, the former requires you to attach it and sew it in yourself. You can sew the sew-in interfacing onto the garment like another layer of fabric, giving it a more natural shape.

If you have a textured fabric or a fabric that can’t be ironed, sew-in interfacing is ideal for you. If you’re a beginner, we recommend that you do not use this interfacing because you may not be able to handle multiple layers of the fabric on your sewing machine.

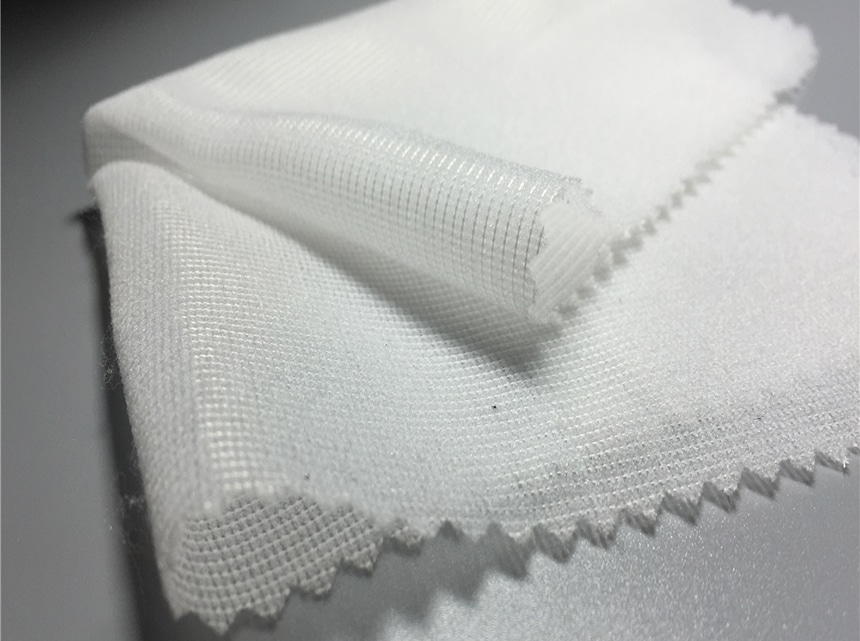

The woven interfacing looks like the typical regular woven fabric, but it’s thicker. It features a selvage as well as a grainline, making it important for you to follow the grainline like you would when you’re cutting out the main fabric. No doubt, working with this material is quite tricky. So, it’s no surprise that it is often used for fine materials like silks and sheers.

Non-woven interfacing, like its name suggests, is the opposite of woven interfacing. It is made by felting or bonding fibers together without a specific grainline or direction. Non-woven interfacing doesn’t unravel, so you can cut it into any direction you desire and it won’t fray. Moreover, it is often regarded as the simplest material to use and is ideal for most garments.

The knit interfacing is generally the best fit for a knitted or stretchy fabric. It is made by knitting the fibers together, allowing you to maintain your garment’s stretchiness. Using woven interfacing on a knit fabric, for instance, will reduce the stretch properties of the fabric. Therefore, you should use knit interfacing if your fabric requires it.

As we have hinted several times earlier, you need interfacing fabric to make your fabric more stable and stiffer or to make an area stronger. It can also give your sewing project some body and shape.

Essentially, the stability of your garment is ensured by interfacing fabric.

The worst nightmare of any dressmaker is having their project ruined by an avoidable mistake. You don’t want that to be you, so you must not choose the wrong type of interfacing for your project. Below are some tips to help you choose the right interfacing fabric for your garment:

The dream of every dressmaker is to make garments that look great on those wearing them. That dream may not realize without the use of interfacing fabric. As we have mentioned countless times in this article, interfacing fabric gives stability and shape to a garment. It’s not enough to decide to use interfacing fabric, it’s also important that you choose the right one for your seeing project so you don’t ruin it. We hope you now know the ideal interfacing fabrics for specific fabrics.